Making of Lenticular lens sheet

A method is given for producing a lenticular lens sheet that consists of improved optical characteristics. The method consists of different steps of providing a platen. It includes a series of grooves formed to define a series of parallel ridges, positioning a formable material sheet next to the platen, making the sheet formable by heating it, and applying a differential pressure to the sheet forcing it into contact with the platen ridges.

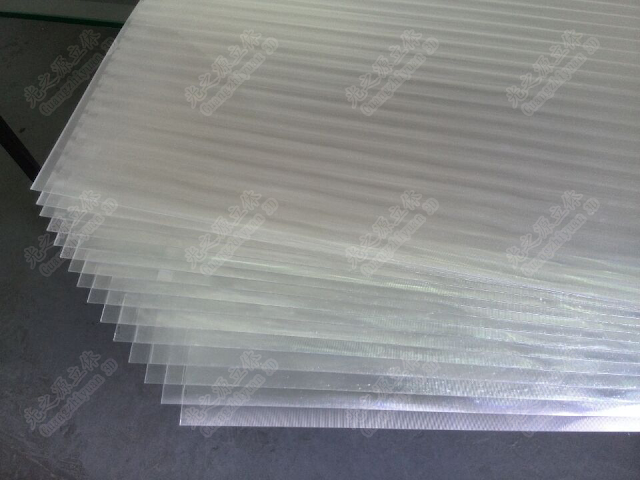

A lenticular lens sheet having a plurality of parallel lenticules is produced by this process. Each lenticular has a catenary surface which consists of a non-uniform radius of curvature that is greatest at the center of the lenticular and smallest at its outer edges.

Generally, this invention is somewhat related to lenticular lenses but maximum resembles thermoformed lenticular lens sheets.

In multiple-image display devices, the use of lenticular lens sheet China is a well-established practice. Such display devices typically consist of a printed sheet or image panel that has a composite image defined by interlaced image bands. Over the printed sheet, a transparent sheet having a plurality of elongate, parallel lens elements, or lenticules, is placed. Concerning the lenticules, the image bands are situated in such a way that the display device exhibits different images when viewed from different lines of sight.

There has been the use of multiple-image display devices for many years, especially for relatively small devices such as cards, buttons, pins, and other novelties, especially in larger displays such as billboards, etc. There were attempts made to make use of lenticular display devices. However, producing an array of lenticules large enough for such applications has proved to be a difficult and expensive endeavor.

Through a variety of established methods that includes injection molding, compression molding, embossing, machining, extruding, and casting, the manufacturing of lenticular lens sheets is currently accomplished. Along with being unable to inexpensively form large lenticular lens sheets, these conventional methods are quite slow and expensive and often need large, complex machinery. Furthermore, in making lenticular lens sheets of different sizes and shapes they cannot be used, and due to this many lenticular lens sheet suppliers do not prefer keeping them.

Follow our Facebook and Twitter for more information about our product.

Comments

Post a Comment