Exploring Lenticular TPU PVC Printing: Tips for Stunning Visual Effects

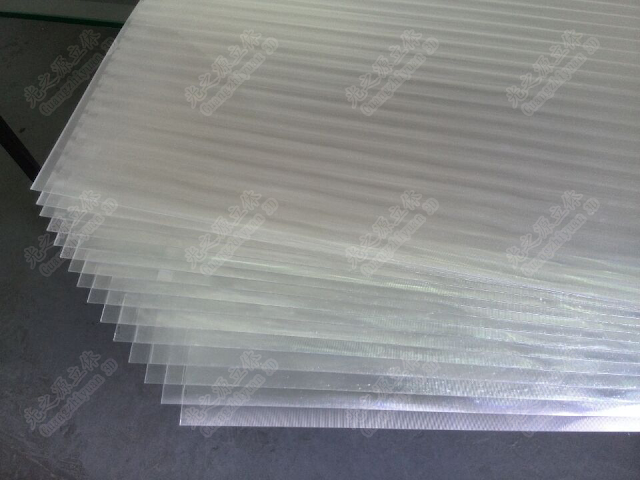

Lenticular printing, including Lenticular tpu pvc printing , may appear difficult, yet it is a concept that many of us have accidentally applied in a variety of ways. Lenticular printing is a specialist method that uses lenticular lenses—tiny lines made of plastic—to generate images that appear to be in motion or with depth. Most typically, it is used to show changing images depending on the viewing angle. How It Works Image Preparation : The adventure begins when we prepare the digital images provided by the client. Depending on the intended effect, the pictures are carefully cut into thin strips. Interlacing : The photographs are meticulously stitched together in a predetermined order to form a composite image. While this composite may not appear particularly pleasing in its raw state, it serves as the large lenticular poster for the lenticular effect. Lenticular Lens Applications : An interlaced image is printed on the back of a lenticular lens sheet for lenticular printing. This sh...